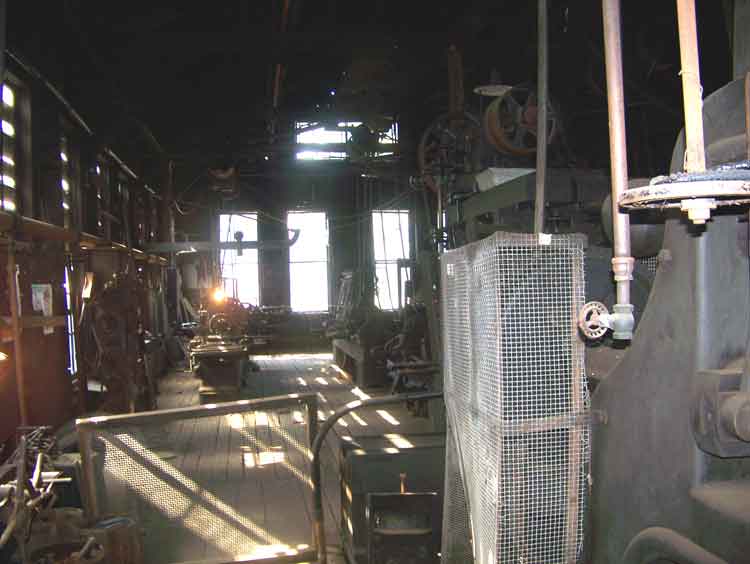

The shops complex at the EBTRR's Rockhill Furnace headquarters included a locomotive shop area where equipment repairs and rebuilds took place. Here machinists worked with lathes, shears, punches, rollers, planers, presses and brakes. Repair work could include fabricating and replacing parts, replacing or contouring tires and flanges, trueing axles and rebuilding the car fleet. Major rebuild work would include firebox replacement, staybolt work, tube and flue replacement and cylinder replacement. A wreck might be cause for a whole bunch of this work at one time. Although the work was directly done by machine with human hands, the machinery itself was often very large. Above we see the larger metal roller, EBTRR did not manufacture boilers, but it made other very large cylinders such as the smokestacks from its shop boilers and the foundry furnace. Notice the lone light fixture, most of the shop's lighting was natural sunlight from the many windows. Some other equipment in this photo is a device to rattle off scale from the inside of boilers tubes fit to be reused ( a practice that is not allowed today ) and an early arc welder ( most welding was done by forge and hammer in the blacksmith shop ). A small forge in this area was for minor reheating work needing during machining processing.

The machinery was powered by a single steam engine running a line shaft and pulley system. These shops and the machines in them were developed before the wide-spread use of electric motors. Two large Babcock and Wilcox boilers provided power to the 125 horsepower steam engine (two were required because of maintenance downtime, one would always be available) . A large pulley on the steam engine was connected by a belt to the line shaft that ran through the shop and the connected blacksmith shop and foundry. At each machine location, another set of pulleys and belt ran power down to the machine. Multiple set of pulleys on the shaft and on the machine allowed for different speeds and idling, the operator had to carefully move the belt from pulley to pulley ( much the same as on a geared bicycle ). As the shop tour guides like to point out, the operator who broke a belt in this process was in for a hard time because the whole line shaft had to be shut down to fix the belt. Some of the machines operated by hydraulic power, in that case the line shaft powered a hydraulic pump that was integrated into the punch, wheel remover, hammer, etc. Later on, Westinghouse proposed to the EBTRR to replace the line shaft system with electric motors on each machine; to make their case they calculated that it took 14 horsepower to run the line shaft when it was idling. The railroad did not make the switch because of their investment in equipment specially designed for the shaft and pulley system and because the steam boilers were needed for other purposes. The boilers ran a dynamo that supplied electric power to the shops, to the station/headquarters and to the superintendents house; and the shops had a central air compressor that piped air compressed air through the shop. In addition, EBTRR would have to pay for electricity, but it got steam power from the coal that its sister company mined.

In their work, shop employees often used specifically made tools forged in the blacksmith shop. Each tool was to be returned to its place at the end of each day on this rack. Some tools only had one use, for example to reach a specific bolt on one of the locomotive and might only be needed once a year, so misplacing it was a major annoyance. Stored on the other side were more tools including the alligator wrench, a tool frowned on by the foreman that would fit a variety of bolts and nuts. Multiple shelves held scores of taps, dies, drills and cutters.

The shops had several lathes to do a variety of machining work. The two shown here are very similar to a modern lathes although one dates back to the 1860's and likely Platt Cathell would have used a similar one. Other more specialized lathes in other areas of the shop are the the wheel lathe and the axle lathe. Notice that the one lathe has a gantry crane; this was an exception to the normal case where the heavy railroad equipment was hand lifted onto the equipment by human force. Platt Cathell wrote that his Civil War injury when he fell down a gangway and landed on a protruding object caused him suffering in the heavy lifting at his job in Grafton. The shop tour guides point out that none of the safety shields and other current employee protection were present in the railroad shop of the 1800's; the shops that Platt Cathell worked in had all kind of dangers that often threatened life and limb. Also notice that the shop had a wooden floor. This floor was not for the comfort of the workers, rather it was to keep from damaging the wheels, axles and other machined products as they were hand rolled from location to location; the shops had no conveyor system. Other buildings in the complex had packed earth floors.

The Rockhill shops included a set of connected buildings using the line shaft system; those being the blacksmith shop and the foundry. The foundry is where arguably the most skilled employees worked. Their job was to completely fabricate replacement parts including grates, cylinder castings and hundred of other parts seen here on Number 13 and the other Baldwin locomotives. The lower, large diameter smokestack marks the location of this building where workers fed hand-selected scrap metal into a large refractory furnace that melted the metal which was then poured into handmade sand or clay molds of the desired object. It took other skilled employees to built wooden mockups of the desired object from which the molds were repeatable made (each casting required a new mold which was destroyed in the process ). Because of structural problems with the buildings, the foundry and blacksmith shop are not on the current shop tour but a similar smaller operation, frozen in time, can be seen nearby in Hopewell, PA ( maintained by the local senior citizens group who wonder if anyone will care to keep their museum going when they pass ). The EBTRR blackmith shop features two trip hammers that probably guaranteed hearing problems in the blacksmiths assigned to that area. Also attached to this group of buildings is the car shop, complete with line shaft drive woodworking tools where rolling stock was assembled and is still repaired. Early wooden coal cars were completely built at the shop while later steel cars were assembled from kits and then later completely rebuilt here. The EBTRR hand-built cabooses number 27 and 28 that are still in use. Other disconnected buildings include the roundhouse and the paint shop which still serve their purpose.

Although Platt Cathell was a skilled worker and railroad jobs were often obtained by family connections, Platts unusual choice of a farm far from his work resulted in only one of his younger sons following him into railroading (perhaps as he planned); that one son was Will, a locomotive engineer working out of Rowlesburg. The other sons followed Platt's other vocation of farming, although they often had to supplement that income from work whenever they could find it. The subsequent generations of West Virginia Cathell's however had several of the men working for the B&O Railroad including my father, Carl M. "Mitchell" Cathell. These jobs up until about the time of my dads retirement offered fairly good employment although in early years one could expect to be "bumped" and perhaps travel a ways off to find work or tough it out until things picked up. The railroad today, due to automation, outsourcing and the downgrading of the St. Louis mainline to a regional service offers far less opportunities to people in the Alleghenies of Preston County.

Use this link to go to the Cathell Family in West Virginia Home Page

Green Valley, West Virginia

August 4, 2007

Green Valley, near Etam West Virginia. Platt Mitchell Cathell homestead. Currently owned and occupied by Gerald "Pete" Cathell, grandson of Platt M. Cathell

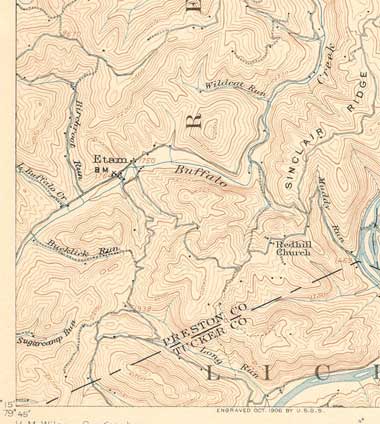

1907 Map of Etam West Virginia. The Cathell homestead is just off of this map to the southwest.

Platt and Sarah, as well as many of their offspring are buried in the Etam Methodist Church cemetary.

| Name: Cathell, George E. | Year of Birth 1865 | Year of Death: 1932 | Birth Place: Baltimore MD |

| Spouse: Sarah E. Robinson | Spouse Birth/Death:1867-1954 | Burial:Etam Cemetary | Child: Roy Cathell 1900-1901 |

| Child: Clarence M. Cathell 1890-1983 | Child: Bertha I. Cathell Britton1891-1973 | Child: James A. Cathell 1895-1964 | Child: Nora A. Cathell 1893-1983 |

| Residence: Green Valley WV | County: Preston | Occupation: Farmer | Notes: |

| Name: Cathell, Joseph Huvington | Year of Birth 1868 | Year of Death: 1964 | Birth Place: Baltimore MD |

| Spouse: Callie V. Adams | Spouse Birth/Death:1884-1960 | Burial:Etam Cemetary | Child: Perl A. Cathell |

| Child: Edith J. Cathell | Child: Dora M Cathell | Child:Earl C. Cathell | Child: William E. Cathell |

| Child: Elsie E. Cathell | Child: Dorothy C. Cathell | Child:T.Gordon Cathell | Child: W. Donald Cathell |

| Residence: Etam WV | County: Preston | Occupation: Farmer | Notes: 95 years old at death |

| Name: Cathell, James Mitchell | Year of Birth 1860 | Year of Death: 1941 | Birth Place: Baltimore MD |

| Spouse:1) Carrie Coburn 2) Annie Turner | Spouse Birth/Death:__________ | Burial:Etam Cemetary | Child:Virgil Cathell |

| Child: Claude Cathell | Child: | Child: | Child: |

| Residence: Belington WV | County: Barbour | Occupation: | Notes:Died in Rowlesburg at Will's |

| Name: Cathell, Steward H. | Year of Birth 1870 | Year of Death: 1953 | Birth Place: Baltimore |

| Spouse: Cyrena May Lipscomb | Spouse Birth/Death:1871-1952 | Burial:Etam Cemetary | Child: Thomas Oscar Cathell |

| Child: Anna L. Cathell | Child: Harry Ervin Cathell | Child: Lula Mabel Cathell | Child: Elmer Neal Cathell |

| Child: Orville Ross Cathell | Child: Theodore Platt Cathell | Child: Boyd Williard Cathell | Child: Stewart Lee Cathell (loved cake) |

| Child: Goldie Grace Cathell | Child: Everett McKinley Cathell | Child: Mary Katherine Cathell | Child: Kenneth Hall Cathell |

| Child: Arthur U. Cathell | Child: Avril Cathell | Child: Robert W. Cathell | Child:Ruth M. Cathell |

| Residence: Hepzibah Community | County: Taylor | Occupation:Farmer | Notes: |

| Name: Cathell, William Luther | Year of Birth 1878 | Year of Death: 1956 | Birth Place: Green Valley -Etam, WV |

| Spouse: Elsie M. | Spouse Birth/Death:1883-1959 | Burial:Etam Cemetary | Child: Merrill (Myrl)Cathell |

| Child: Charles (Charley) Cathell | Child: | Child: | Child: |

| Residence: Rowlesburg WV | County: Preston | Occupation: Engineer, B&O | Notes: Pension card in Rowlesburg book |

| Name: Cathell, Charles (Charley) | Year of Birth 1880 | Year of Death: 1952 | Birth Place: Green Valley -Etam, WV |

| Spouse: Mable (Mae)Gaines | Spouse Birth/Death:1887-196_ | Burial:Etam Cemetary | Child:Betty (Cathell) Sohn |

| Child: Dolly M (Cathell) Bolyard Dutton 1914-2002 | Child: Gerald (Pete) Cathell, Green Valley, WV | Child: Richard (Rich) Cathell, Chesapeake, VA | Child: Violet (Cathell) Carver |

| Child: Augusta Cathell | Child: Mildred M. Cathell | Child: C. Harold Cathell | Child: |

| Residence: Green Valley, WV | County: Preston | Occupation:Farmer | Notes: bought homeplace from siblings |

| Name: Cathell, Jane | Year of Birth 18__ | Year of Death: 19__ | Birth Place: Baltimore MD |

| Spouse: Thomas Springs | Spouse Birth/Death:_______ | Burial:_______ | Child: |

| Child: | Child: | Child: | Child: |

| Residence: | County: Taylor | Occupation: | Notes: |

| Name: Cathell, John Wesley | Year of Birth June 22, 1872 | Year of Death: August 25, 1951 | Birth Place: Baltimore, MD |

| Spouse: Jane Haymon or Layman | Spouse Birth/Death:_______ | Burial:Concord Church | Child: Callie Cathell Corley |

| Child: Johnnie Cathell | Child: Ralph William Cathell | Child: Daisy Cathell | Child:Howard Cathell |

| Child: Mitchell Cathell (of John, not of Clarence) | Child: Carrie V. Cathell | Child: Inez D. Cathell | Child:Myrtle E. Cathell |

| Child: Bretsel L. Cathell | Child: | Child: Clifford B. Cathell | Child:Blanch Cathell |

| Child: Dolly P.Cathell | Child: Bud Cathell | Child: Sarah E.Cathell | Child: Nellie R. Cathell |

| Residence: rural Belington WV | County:Barbour | Occupation: Farmer | Notes: |

| Name: Cathell, Jonathan | Year of Birth abt 1873 | Year of Death: ? | Birth Place: Baltimore MD |

| Spouse: _____ | Spouse Birth/Death:_______ | Burial:? | Child: |

| Child: | Child: | Child: | Child: |

| Residence: | County: | Occupation: | Notes: Jonathan might be John Wesley-above? |

| Name: Cathell, Martha W | Year of Birth abt 1876 | Year of Death: ? | Birth Place: ___________ |

| Spouse: _____ | Spouse Birth/Death:_______ | Burial:? | Child: |

| Child: | Child: | Child: | Child: |

| Residence: | County: | Occupation: | Notes: |

| Name: Cathell, Rutherford B. | Year of Birth abt 1876 | Year of Death: ? | Birth Place: West Virginia |

| Spouse: Grace E. Francis Cathell | Spouse Birth/Death:12/25/1879/? | Burial:? | Child: |

| Child: | Child: | Child: | Child: |

| Residence: Harrison Co. WV | County: | Occupation: | Notes: Married Grace 1899 |

|